Williams Aerospace Engineering have a wide range of specialist services available all under one roof at our recently refurbished and expanded Southampton premises.

This page will give you a brief overview of most of them, please check out each individual page for more detailed information.

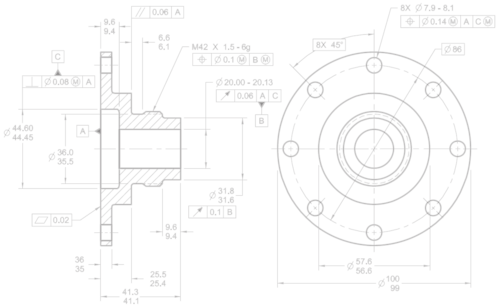

CNC 5 Axis Turning/Milling centre, CNC 4 Axis Milling, Gear Cutting, Grinding, Honing, Lapping & Minor Assemblies for the Aerospace, Nuclear, Marine, Motorsport, shipping & general machining industry requirements.

Below are our core competencies, please follow the links to find out more about each speciality, and how we can assist you in your particular requirements.

> CNC Turning

Williams Engineering has many years’ experience in CNC Machining, Turning and Milling our 5 Axis CNC machining centre turn/mill enables us to manufacture items with turned diameters, flats and cross-holes in one operation. Find out more

> CNC Milling

Duguard & Bridgeport 3 & 4 Axis CNC machining centres X Axis 660mm, Y Axis 520mm, Z Axis 510mm. Twin arm 24 station ATC carousel type. Standard spindle speed 8000rpm Find out more

> Gear Cutting

With over 40 years experience in Gear Cutting Williams Engineering are able to manufacture and supply many types of gears. Find out more

> Grinding

Williams Engineering are able to offer a number of differing types of grinding to suit your particular project. Find out more

> Honing

As some of our customers require bores with very fine surface finishes, we specialise in Match Grinding. Honing together with Solid Lapping we can achieve surface finishes down to 0.5 Micro inch Find out more

> Lapping

Precision Lapping services for Flat Lapping and Polishing to meet customer demands

Flat Lapping up to 150.00mm Dia. 150 x 150 x 50mm (L x W x H) can be lapped obtaining tolerances down to 1 Light Band Flatness, with a surface finish down to 0.5 Micro-inch CLA.

Cylindrical Lapping of Bores, Range from .046″ (1.168mm) to 1.500″ (38.10mm) Dia. obtaining surface finishes down to 0.5 Micro-inch CLA Find out more

Quality

With the latest accreditation to AS 9100, our comprehensive temperature controlled Inspection department, offers a wide range of measuring capabilities

Roundness, Cylindricity and profile measurement

CNC Vision & Probe CMM

Manual CMM

Touch Probe Projector

Air Gauging, Surface Finish, Hardness Testing (Rockwell C only)

All Measuring equipment is calibrated externally by a NAMAS approved laboratory and supported by NAMAS certificates, to meet AS 9100 & BS EN IS 9001 requirements. Find out more.